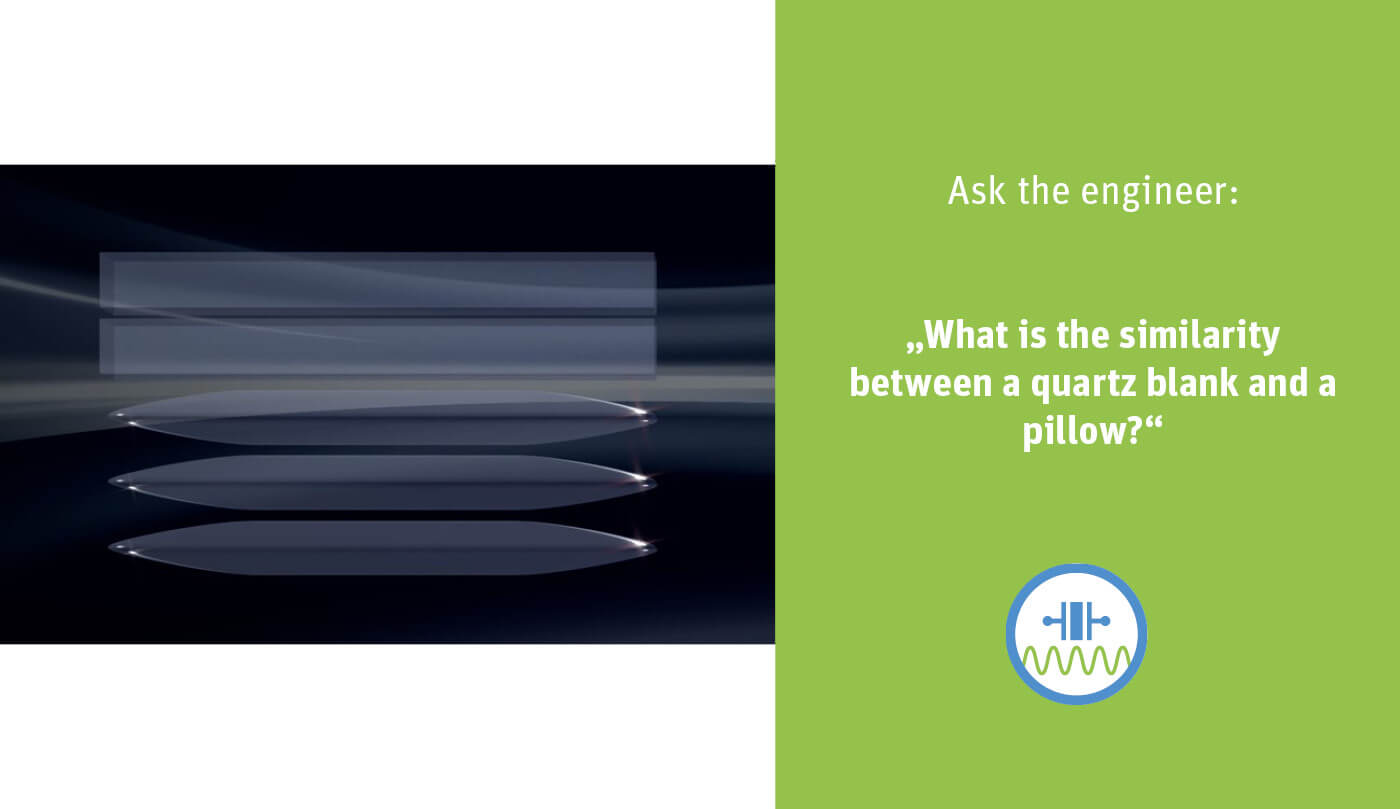

Do you already know the similarity between a quartz blank and a pillow?

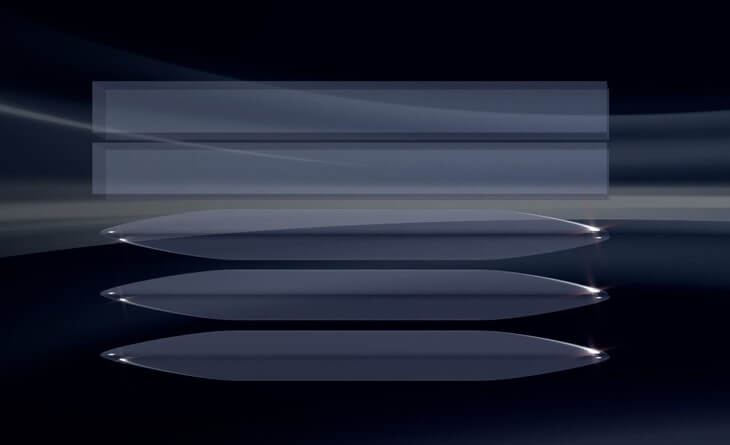

Exactly! Both have the same shape.

The so-called “bevelling” or “contouring” in the production process of quartz blanks results in the characteristic lens shape of quartz blanks. “This procedure is mainly used for ‘thicker’ blanks, which are in the low frequency range, i.e. around 8 – 20 MHz”, explains Mathias Laskus, an engineer from the Technical Support Department of Frequency Control Components.

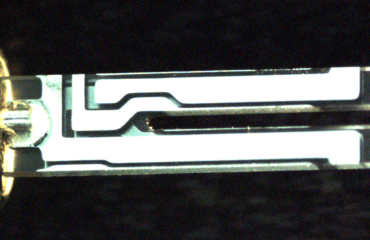

The quartz blanks are placed in a steel cartridge together with ultra-fine lapping powder and moved in a centrifugal drum lapping machine until the desired shape is achieved. As shown in the picture, the shape resembles that of a pillow.

“On the one hand, this approach ensures that assembly into certain holder systems is simplified. On the other hand, the vibrating area of the quartz blank is restricted to the central part of the blank,” says Mathias Laskus. Reducing the size of the vibrating area means that spurious resonances are reduced.

Spurious resonances are frequencies that occur near to the nominal resonant frequency and are therefore undesirable. Already during the design of the blanks, our designers pay special attention to avoid or optimally suppress these spurious resonances. Unwanted resonances can additionally be effectively suppressed by varying the size of the applied electrode. Experienced quartz developers already take these problems into account during the whole development process to supply a quartz crystal of highest quality.

Deutsch

Deutsch