Nowadays, Christmas without quartz crystals is unimaginable! Why? Even the modern time switches for outdoor lighting need a quartz to have an accurate time base. Also, a lot of our gifts are based on state-of-the-art electronics. Cell phones, smartwatches, PCs – they all need highly accurate frequency giving components to communicate with each other. Without this communication, their usefulness is severely limited, or even non-existent. The devices usually receive the necessary driving rhythm from a quartz, the modern “heart” of such a device.

“Oscillating crystals change their behavior and electrical properties as a function of temperature,” explains Mathias Laskus, engineer for frequency giving components at Jauch Quartz. Hence, temperature changes lead to frequency deviations. This deviation is measured in “parts per million (ppm)” – which means:

1ppm = 1 part per million = 0.000001 = 0.0001%.

The temperature sensitivity of AT-cut crystals

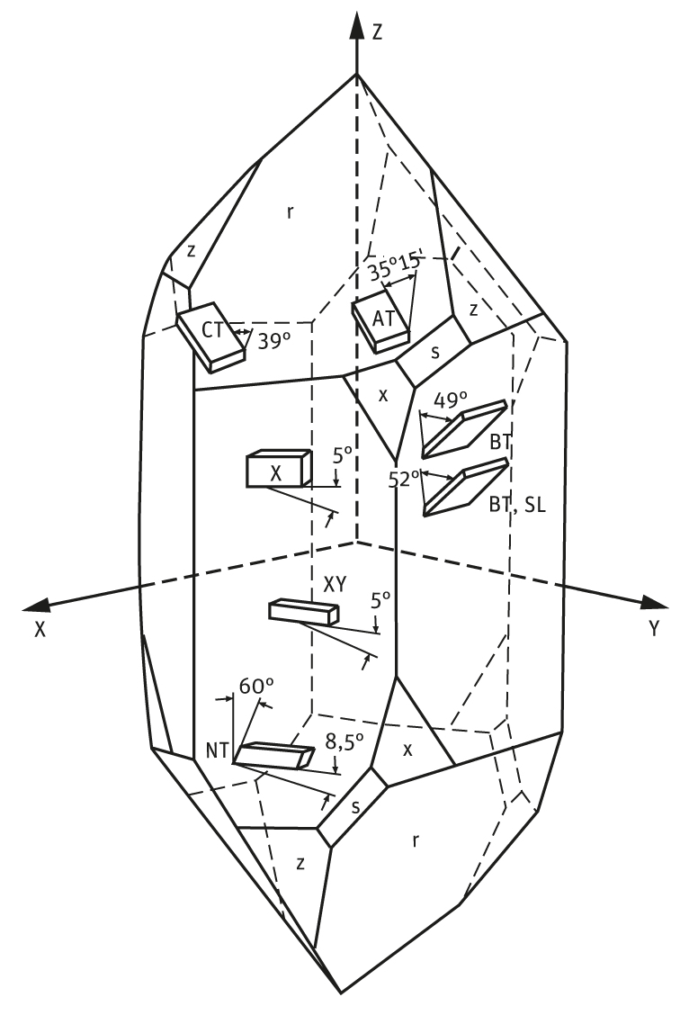

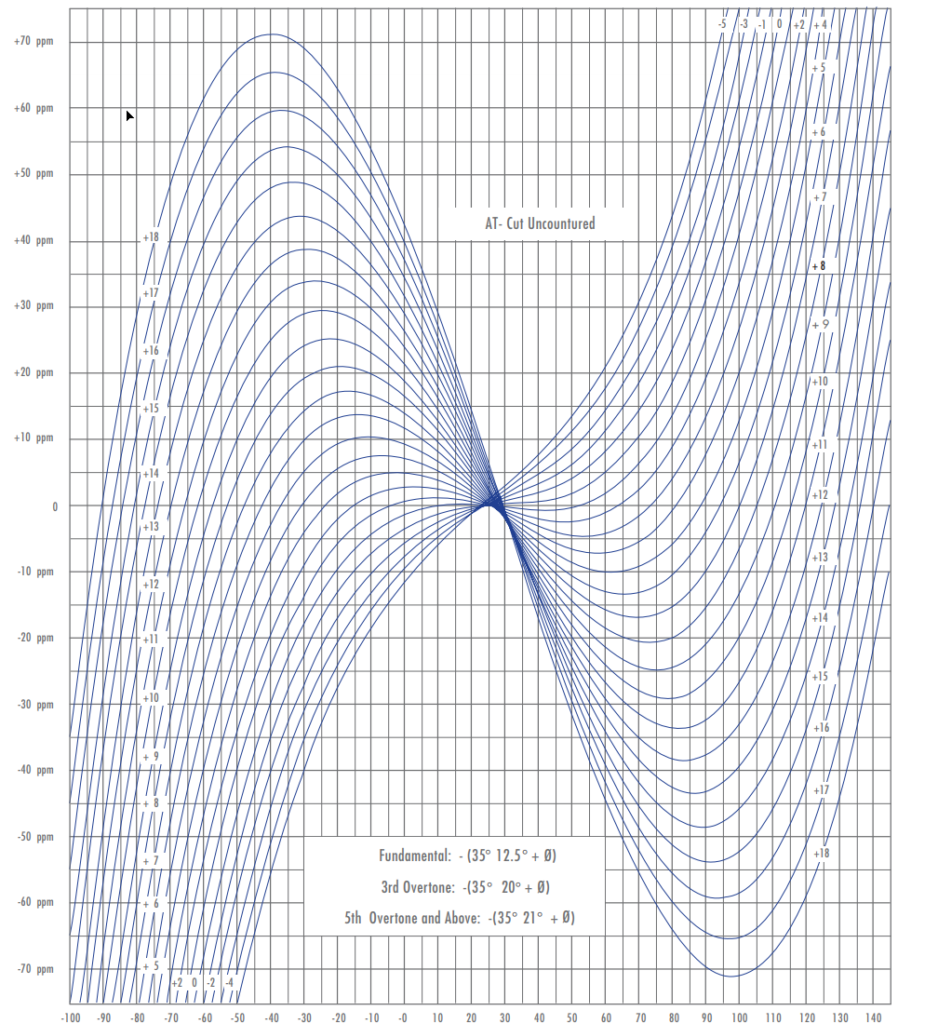

Oscillating crystals in the MHz range are also called AT-cut crystals. They contain thin quartz wafers, the so-called quartz blanks. AT-cut quartz blanks are cut from the quartz block at the AT angle at 35°. The thickness of the blanks is essentially responsible for the fundamental frequency at room temperature. However, the exact angle at which this quartz blank was cut from the quartz block is responsible for the deviation of the frequency at other temperatures. If the ideal angle of 35°15′ is hit very precisely in the cutting process, the quartz becomes less sensitive to temperature.

On the left you can see different cutting angle options.

The temperature sensitivity runs as a function of a cubic parabola. During cutting, even minimal inaccuracies in the range of single angular seconds lead to a rotation of the curve around the inflection point. This worsens the temperature sensitivity in the desired temperature range for the subsequent application. During the manufacturing process of the blanks, the perfect cutting angle can only be achieved to a limited extent due to the possible maximum manufacturing accuracy. Therefore, the manufactured blanks must be sorted according to their deviation and used for the appropriate crystals according to their accuracy.

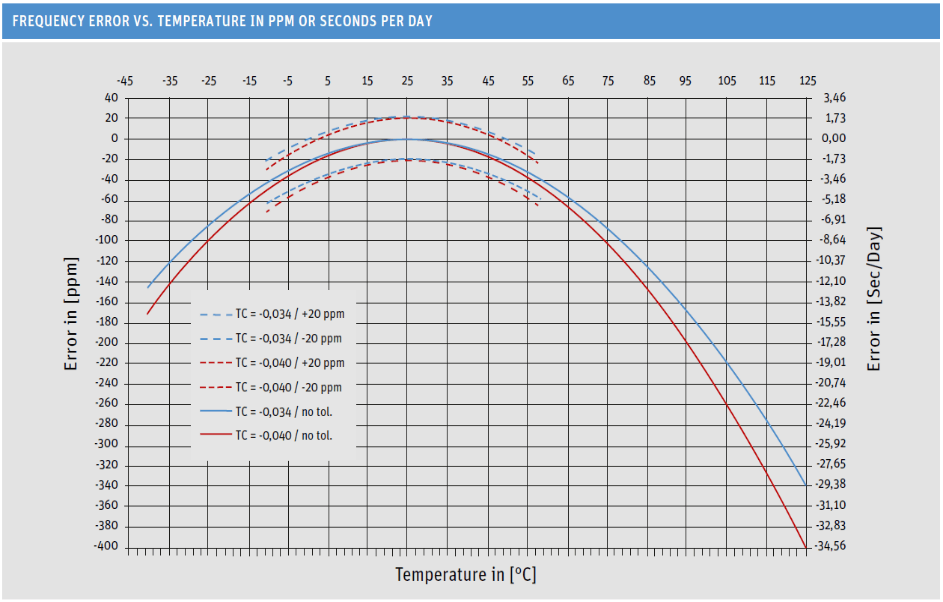

Temperature dependence of tuning fork crystals

For tuning fork quartz crystals (also called clock quartz crystals) the function of an inverted parabola describes the temperature dependence of the frequency. The vertex of the parabola at a temperature-dependent frequency deviation of 0 ppm is in this case at 25 °C. At lower and at higher temperatures, for example to the left and to the right of this point, the frequency falls increasingly – and according to a quadratic curve. If the quartz in the circuit is correctly adjusted, there will be a temperature-related lag, for example with a RealTimeClock. The developer of an application must definitely take this into account.

What does this mean for the application?

Both temperature curves show that extreme temperatures have an influence on the frequency of quartz crystals. For the majority of applications, a slight temperature-related change in frequency, for example of +/-15 ppm in the range from -40 °C to +85 °C, is not a problem. However, if a more accurate frequency is required, it is recommended to use a temperature compensated crystal oscillator, called TCXO. This provides a very high frequency accuracy in the range of a few ppm even over wide temperature ranges.

We will be happy to advise you on the selection of the right clock generator for your application.

Deutsch

Deutsch

I’m curious what leads to the temperature operating limits?

I have an application that sees 105C ambients, so require parts rated for at least this.

Is the main issue with higher temperatures just the larger frequency deviation, or are there failure concerns with operating xtals at higher temperatures?

Hi Mikkel,

thank you for your question.

I talked to our engineer Mathias Laskus about your questions and this was his answer:

“You need to select a part with extended temperature range. Most of those parts are built with a conductive bond allowing the extended temperature range. To keep the requested stability over that range, only selected crystal blanks with lowest temperature sensibility are used. This leads to a crystal with extended operating temperatures keeping lowest temperature caused deviation.”

I hope that this helps 🙂

Kind regards

Selina