How is the life of a rechargeable battery determined?

Have you ever wondered why you have to recharge your smartphone battery at increasingly shorter intervals after 1 to 2 years of use? Of course, the phenomenon is not limited to the battery in the smartphone – every rechargeable battery inevitably loses storage capacity over time. But what is the reason for this? And how

- Published in Battery Technology

How is the service life of primary lithium batteries determined?

We know lithium batteries mainly from our smartphones, laptops, or smartwatches: all devices that can be recharged again and again once the battery is empty, but not all lithium batteries are rechargeable. Some chemistries, generally CR (lithium manganese dioxide) and ER (lithium thionyl chloride) batteries, may not be recharged under any circumstances. Both types of

- Published in Battery Technology

Customer Success Story: Lunch from the mini-steamer – thanks to battery power from anywhere

Long lines at the microwave in the university canteen, a short lunch break and then the food also loses its taste and vitamins. For the trio of founders of the start-up Nexenic, this was the reason to revolutionize the topic of Mealprep. The product: the Steasy® mobile mini-steamer With Steasy®, food can be heated up

Customer Success Story: Reliable Power Supply for Epilepsy Detection during Sleep

Approximately 1 percent of people worldwide suffer from epilepsy. In numbers, that’s one in 100 to one in 150 people. In 30 percent of them, the disease is even incurable. This means that they are unable to control their seizures with the help of medication. Recurrent seizures are the result. “Seizures that occur during sleep

- Published in Battery Technology, Customer Success Stories

Ask the doctor of chemistry: Why can’t primary lithium batteries be recharged?

Lithium batteries are one of the most widely used types of batteries and serve a variety of applications, including electronic devices and energy storage. We know these batteries mainly from our smartphones, wearables, or cars, which we can recharge time and again. However, there are battery chemistries with lithium that cannot be recharged. These include,

- Published in Battery Technology

Customer Success Story: A durable and certified battery for mBrainTrain’s mobile EEG

Electroencephalography, or EEG for short, is a methodology for measuring tiny brain signals that are quite difficult to capture. You can likely imagine how these tests look like: Participants have electrodes and lots of cables around their heads while being in a lab. However, these complex systems cannot measure the human brain in the natural

- Published in Battery Technology, Customer Success Stories

The Lithium Battery’s Beginnings

Clattering coins, a line of people, and pattering rain: a run-of-the-mill evening scenario in front of a yellow telephone booth. These previously offered the only opportunity to check in with family or friends while on the go. Nowadays, the 140-year era of the telephone booth has come to an end—the smartphone already sealed its fate

- Published in Battery Technology

Customer Success Story: The battery powered motorized positioning arm from Interventional Systems

In minimally invasive interventions, it is very important to work as accurately as possible. The motorized arm for the positioning and holding of medical equipment from the Austrian company Interventional Systems (INS) supports doctors during these interventions. Powered by a Jauch battery, it makes positioning and repositioning instruments easier than ever while keeping them steady.

- Published in Battery Technology, Customer Success Stories

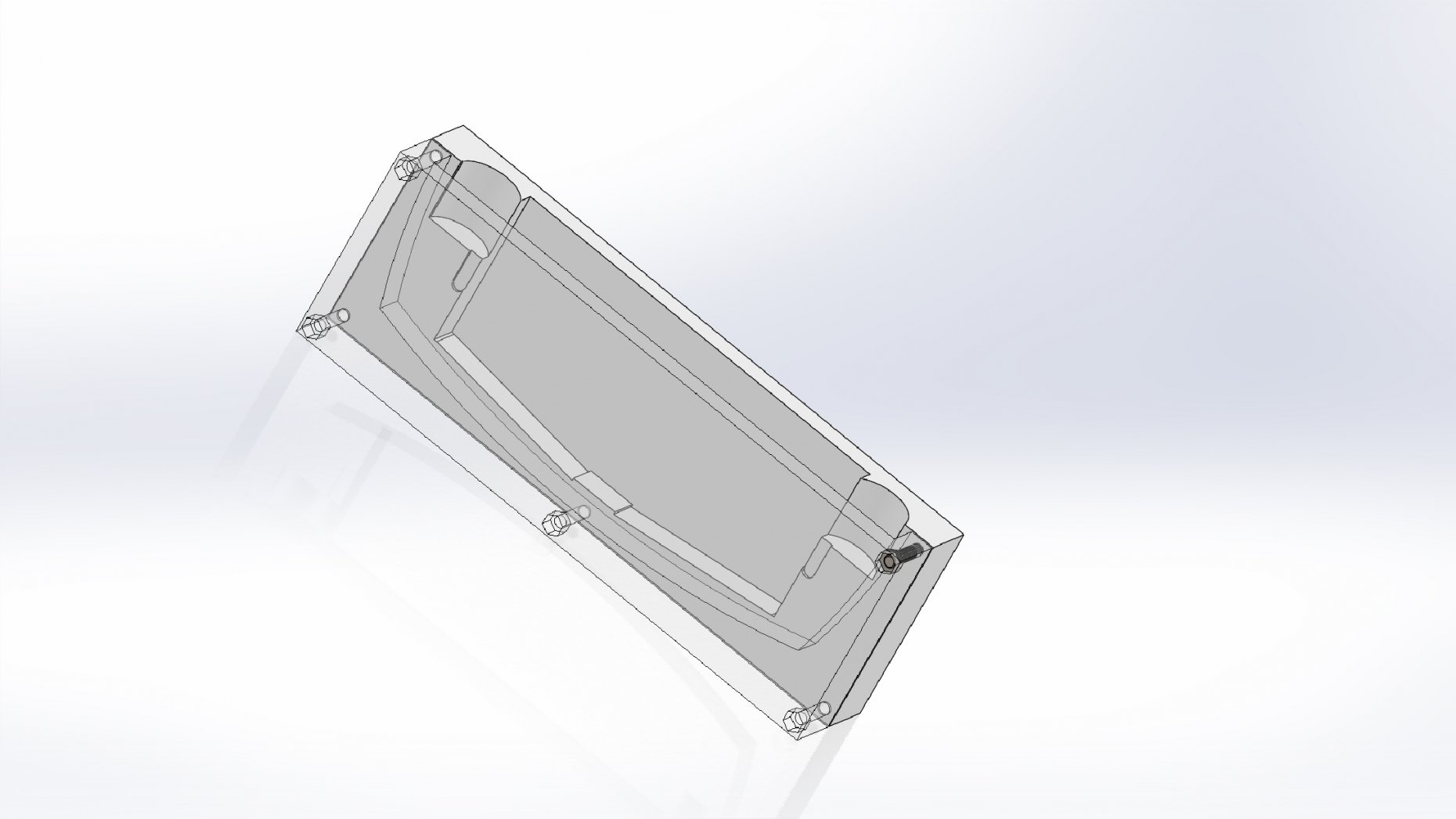

From the 3D printer: a mount for holding the Steasy® battery pack during the UN 38.3 vibration test

There was recently a post on this blog regarding our 3D printer used for making samples and prototypes. The 3D printer allows both our customers and us to enjoy speed and flexibility in various process steps. For instance, this is true for the start-up Steasy®: We printed a mount designed to hold the start-up’s custom

- Published in Battery Technology

Customer Success Story: The tripod for thermal imaging and night vision cameras – a lithium-ion battery for XSPECTER

Founded in October – and on the market within just six months: Start-up XSPECTER has its T-CROW XRII to thank for this success. The product behind this futuristic name is a special tripod for thermal imaging and night vision cameras. The product: A controllable 3D-printed camera tripod The T-CROW XRII is a controllable camera tripod

- Published in Battery Technology, Customer Success Stories

Deutsch

Deutsch