Northh Medical, a MedTech start-up founded in 2017 in the German city of Hamburg, focuses on early detection of congenital heart defects of unborn children in the womb. “Especially in the last weeks of pregnancy, routinely conducted ultrasonographic cardiac imaging reaches its limits,” says Dr. Christian Ruprecht, one of the founders. That’s why Ruprecht and his cofounders have made it their mission to improve cardiac imaging via magnetic resonance imaging (MRI).

Usually the MRI method is excellently suited for the imaging of organs. However, anyone who has ever been inside the MRI tube himself will remember the radiologist’s instruction: “Do not move under any circumstances during the 10-minute examination!”

MRI imaging is very slow, so any movement affects the quality of the image produced. However, as a beating heart is constantly in motion, cardiac imaging via MRI has proven itself to be a very difficult task so far.

The Goal: Cardiac Imaging via MRI

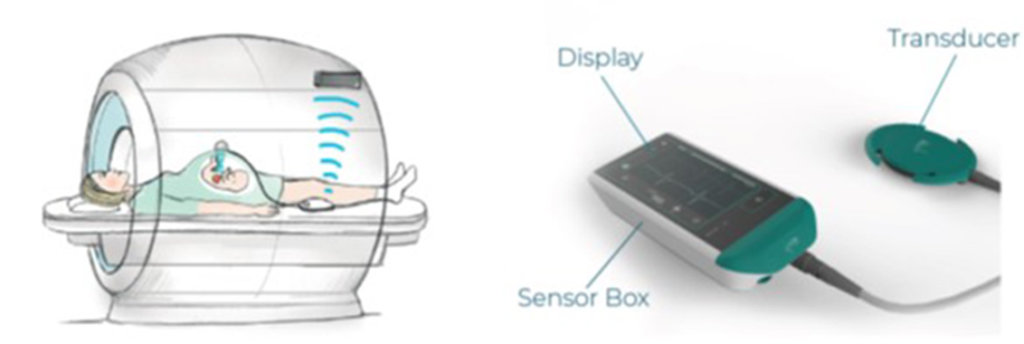

This is where Northh Medical comes into play with its new developed product “smart sync”. “Smart sync synchronizes the heartbeat of the fetus with the MRI. Consequently, the heart can be displayed in much better quality than before,” says Dr. Ruprecht. This enables MRIs to produce cardiac images in diagnostic quality, contributing to the detection of fetal congenital heart defects.

How does it work? First, the device uses an ultrasonic probe to determine the heart rate of the fetus. The probe is connected via cable to the “sensor box”, which receives and processes the signals and transmits them via radio to the “connector box”. The “connector box” is the interface to the MRI device. Through this box, the heart rate information is fed into the imaging process.

“That way images of the heart, in the highest quality, are created without distortions. For the attending doctor, these images are valuable additional resources for the diagnosis,” explains Dr. Ruprecht. Thanks to improved early detection, doctors can better ensure the birth takes place in a clinic where the child can receive appropriate care. On the other hand, it is also possible that the severity of a diagnosis is lower according to the MRI images than assumed after the normal ultrasound examination.

The Challenge: An Amagnetic Lithium Polymer Battery

During the development of “smart sync”, Northh Medical had to deal with several challenges; especially the search for the right battery solution. “We searched for a very long time until we finally found the right partner in Jauch Quartz GmbH,” recalls Dr. Ruprecht.

At first glance, Northh Medical’s requirements did not seem too unusual: a high-performance lithium-polymer battery with an intelligent charge level indicator and corresponding protection electronics. However, taking a closer look revealed the project’s complexity; use in an MRI means the battery must be 100% non-magnetic.

“The MRI generates a strong magnetic field. Any magnetic object, no matter how small, interferes with the imaging process considerably,” says Dr. Ruprecht. “An amagnetic battery is therefore an absolute must for our device. Of all the suppliers contacted, only Jauch Quartz was able to make a suitable offer.”

But which components of a lithium polymer battery are magnetic? Here, too, a closer look is required. “The housing of a lithium-polymer battery consists of deep-drawn aluminum foil and is just as non-magnetic as the electrode materials that are pasted onto wafer-thin aluminum or copper foil. Copper is also an amagnetic metal,” says Dr. Jürgen Heydecke, a Jauch Technical Director who led this project.

The Solution: Arresters Made of Copper

“The devil is in the details, in the arresters, to be exact. These are often made of magnetic nickel,” says Dr. Heydecke. In most other applications, nickel eases the solderability process on the protective electronics. However, for Northh Medical, the use of nickel is a deal breaker.

“We were lucky; a few years ago, we had a customer with similar requirements. When Northh Medical approached us with their tricky demands, we knew what to do,” Dr. Heydecke recalls. Consequently, Jauch replaced the nickel arresters with copper arresters. “This may sound simple, but it requires a great deal of tact and sensitivity in production. Welding copper arresters onto aluminum foil is a difficult process,” says Dr. Heydecke.

In addition to the arresters, the connections between the cells in the battery pack and all the resistors and MOSFETs of the protective electronics must be completely non-magnetic. At the end of this demanding and detail-oriented process, Jauch developed a battery pack with two serially connected lithium polymer cells (4.1 mm x 61 mm x 132mm) with a voltage of 7.4 volts and a capacity of 4,200 mAh. In Addition to the battery’s development, Jauch took also care of the necessary IEC-certification.

Smart Sync is Used Worldwide

Now, prototypes of “smart sync” are used all around the globe. The university hospitals in Lund, Boston, Vienna, Göttingen and Giessen use the device as well as the Medical Center in Tel Aviv. Northh Medical is working on extending their “smart sync” process to adults in the meantime. “The application of ‘smart sync’ for heart imaging via MRI has the potential to completely change the traditionally established ECG procedure”, says Dr. Ruprecht.

More Customer Success Stories

Real Time Tracking with Kontakt io’s Bluetooth Beacons

Deeper’s Smart Fish Finder

Deutsch

Deutsch