Lithium-ion and lithium-polymer batteries currently set the standards in the battery market in terms of performance, cell voltage and service life. While lithium ion batteries are thought to power the vast majority of our cars in the future, lithium polymer batteries are already supplying power to our mobile phones and laptops today.

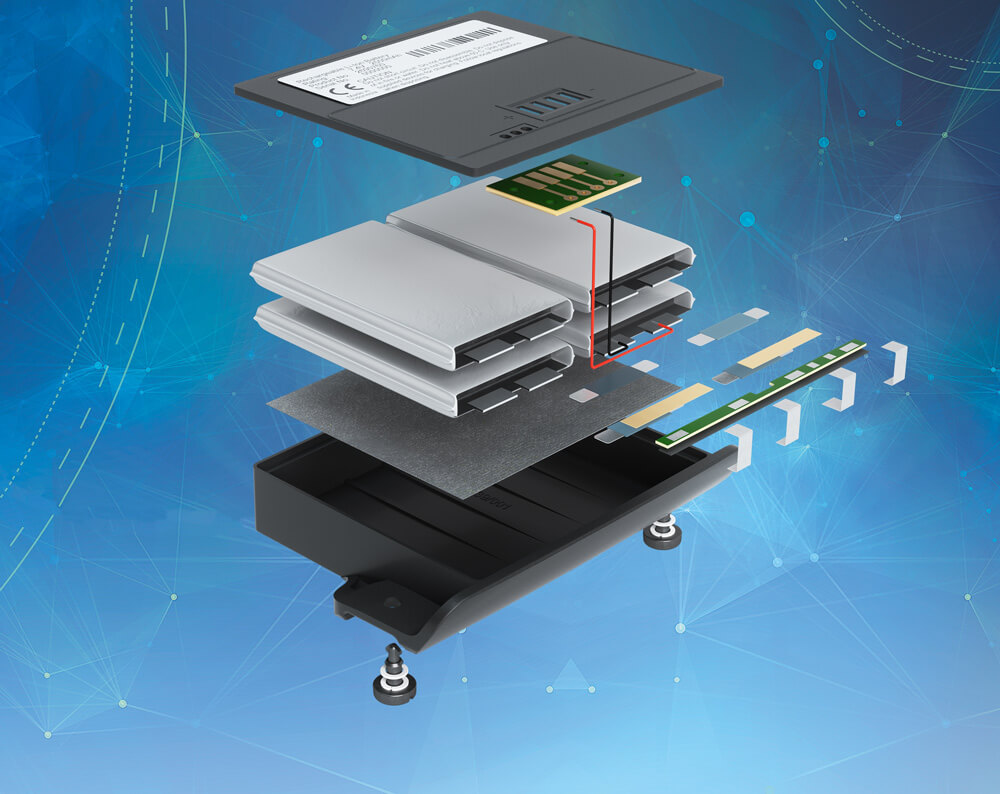

Both cell types are based on an identical cell chemistry, meaning the chemical processes during charging and discharging of the cell are the same. However, lithium ion and lithium polymer cells differ in their construction. Lithium ion cells use a sturdy metal housing of standardized size. The design of lithium polymer cells offers much greater flexibility: instead of a rigid housing, the flat, sandwich-type cells are enclosed by a thin layer of plastic-laminated aluminium foil. This design enables the production of lithium polymer cells in a wide range of different shapes and sizes.

“Our product portfolio comprises more than 100 lithium polymer cells of various sizes and capacities. Developers thus enjoy maximum freedom when designing their applications,” says Timo Schmidt, Head of Battery Technology at Jauch Quartz GmbH.

Important Parameters for the Development of Lithium Polymer Batteries

Besides size and capacity of the cell, the required cell voltage plays an important role in the search for the right lithium polymer solution. The standard voltage for a single lithium polymer cell is 3.6 volts. The cut-off voltage is 3.0 volts and the maximum charging voltage is 4.2 volts. If the application requires a higher voltage, this can be achieved by connecting several cells in series.

In addition, different current load profiles must be created for each battery. These profiles indicate how much current the respective application requires from the battery in any state of usage. The average continuous currents have thus to be specified as well as the maximum pulse currents and pulse lengths. The inrush currents and their length must also be considered.

When thinking about current load profiles, the ambient temperatures to which the application is exposed must be considered, too. Standard lithium polymer cells are built for usage in a temperature range between -20 and 60 degrees Celsius and while charging the cells, the temperature range should be between 0 and 45 degrees Celsius. Special cells are available for use in extreme temperature conditions above or below this range.

Besides all these technical aspects, safety is a vital issue. To prevent short circuits, overcharging or deep discharges, lithium polymer batteries are equipped with protective electronics. Depending on the complexity of the battery, it is also necessary to program an individual battery management system, defining individual switch-off values for the battery, among others.

Finally, there are various legal framework conditions to be taken into account when developing batteries. Every battery must meet the appropriate requirements in order to be approved for sale and transport. Successful certification of the battery according to UL and IEC standards is just as important here as passing the UN 38.3 transport test.

Jauch Quartz – Experts in Developing Batteries

The above-mentioned parameters are the cornerstones of any battery development process. “Of course, we don’t leave our customers alone in this, quite the opposite,” says Timo Schmidt. “We not only procure the right lithium cells for our customers, but also take over the entire development work. We take care of cell selection, program the protective electronics and carry out all the necessary tests and certifications until we finally go into series production with the finished battery”.

In this way, even special customer requirements can be realized. The latest example of the Jauch-engineers’ inventiveness is a completely amagnetic lithium polymer battery that was specially developed for a German MedTech start-up.

Looking for the right battery solution as well? We will be very happy to support you! Here you can find detailed information about our development services.

Deutsch

Deutsch