In the blog posts Ask the Product Manager: Are real rock crystals used for production of oscillating quartz crystals? and Quartz production process: from quartz block to quartz blank, we have already taken a closer look at the first stages in quartz production, what material the quartz blanks are made of and what steps are necessary for a quartz blank with a certain frequency to be created from a quartz block.

We are now at the following point in the process leading up to the finished component: the quartz blank has been produced, even the electrode has already been vaporized and the frequency has been checked. The blank must now be installed into the housing. It sounds simple, but even here there are one or two points to consider so that the final result is a high quality and durable quartz.

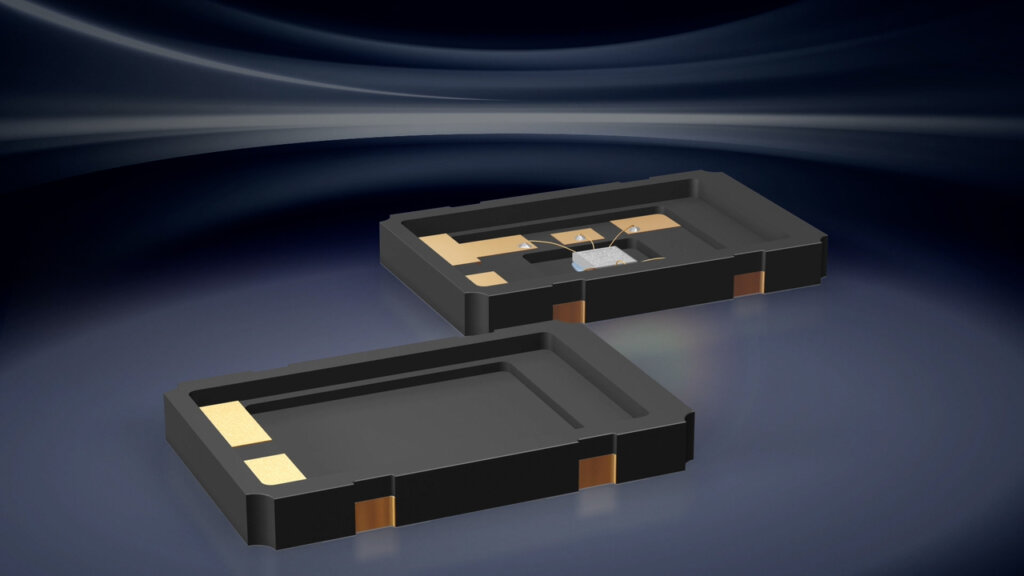

Mounting into the housing

To mount the blanks into the housing, the housing base is first of all coated with conductive adhesive. The next step is to affix the quartz blank.

The final frequency adjustment

Now the frequency is adjusted one last time. Using two different methods, the target frequency is adjusted if necessary. On the one hand, additional electrode material can be vapor-deposited if the frequency is too high. This step decreases the frequency. Alternatively, partial removal of the electrode material with plasma can increase the frequency.

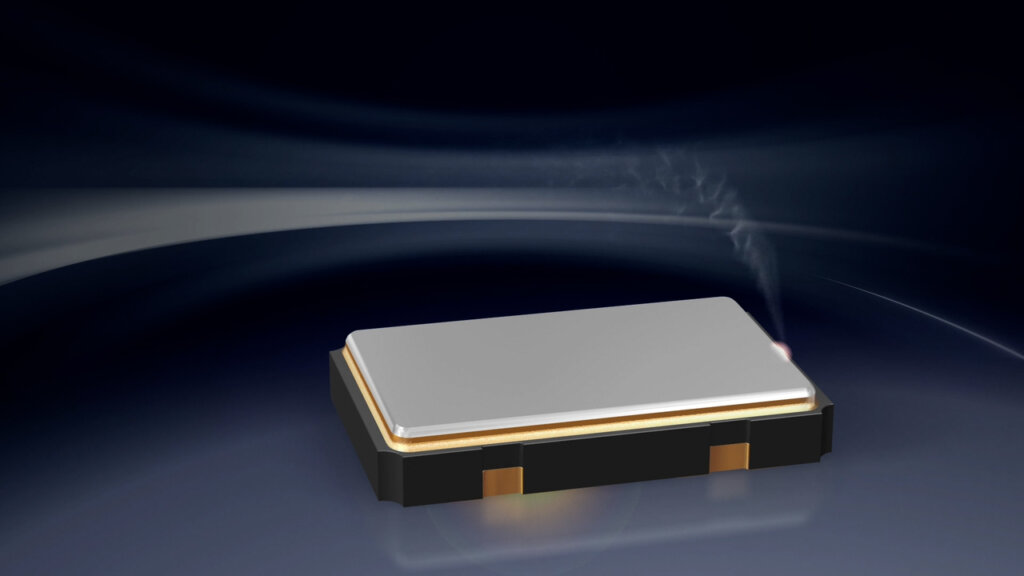

The housing is sealed

Next, the housing is sealed. There are several methods for this. The “Seam Seal” method is often used. In this process, the metal lid and packaging are welded together with electrodes. Find out more about this topic in this blog post.

The final stages

The quartzes are marked with the help of lasers or special inks before they are subjected to final testing, packing and shipping.

Now the quartz crystal is finished and it can be mounted on the plate.

This document sets out all of the stages in the manufacturing process for quartzes in a clear and visual way.

Deutsch

Deutsch