One thing is for sure: lithium battery technology is currently leading the way in the field of mobile power supply. Just look in your pocket: There is no smartphone that is not powered by a lithium polymer battery. Since the Swedish mobile phone provider Ericsson launched the first mobile phone with a lithium polymer battery in 1999, the technology has become an indispensable part of the industry. The reasons are manyfold.

Just like lithium ion batteries, lithium polymer batteries have a very high energy density compared to other cell chemistries and are therefore particularly powerful. At the same time, they are extremely durable thanks to the low self-discharge of the battery cells.

Same Performance, Higher Flexibility

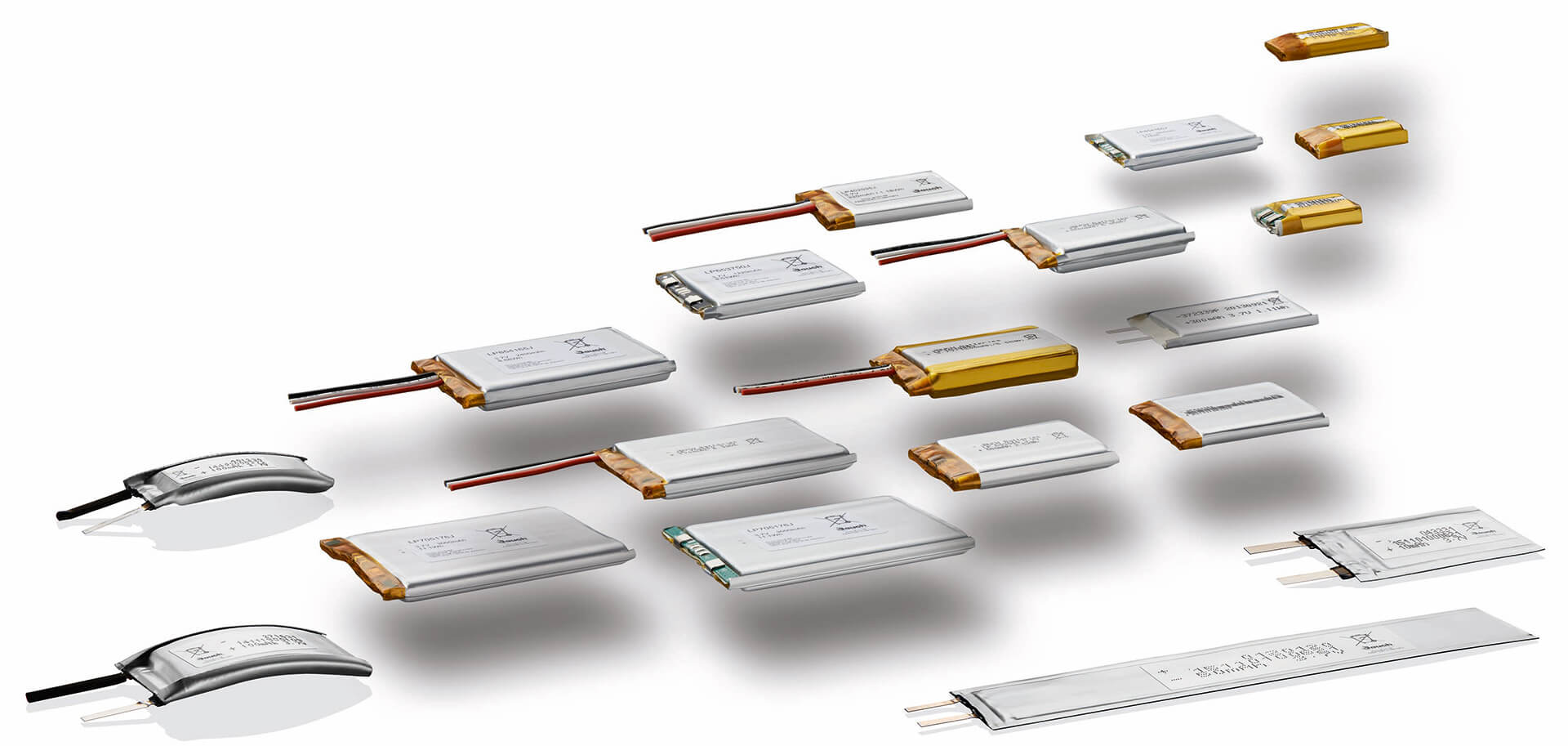

The flexibility of their design makes lithium polymer batteries particularly attractive. While lithium ion cells always have a sturdy metal housing, lithium polymer cells are only enclosed in a thin layer of plastic-laminated aluminium foil. In addition, the sandwich like structure of the lithium polymer cells enables significantly flatter battery designs than what is possible with lithium-ion batteries. Thanks to these two factors, lithium polymer batteries are available in almost every imaginable size. Even curved designs, for example for fitness bracelets or smartwatches, as well as ultra-thin batteries with a thickness of less than one millimeter are feasible.

Due to their flexibility and performance, lithium polymer batteries are in demand not only in mobile communications and consumer applications, but also in other industries such as medical technology. At the same time, however, the high voltage and the absence of a protective metal housing pose new challenges.

Safe Handling of Lithium Polymer Batteries

First, it must be considered that the cells of a lithium polymer battery expand while charging. If the battery is discharged, the cell reduces its thickness. This phenomenon, known as “swelling”, can cause lithium polymer cells to expand by up to ten percent of their original thickness over several cycles. Manufacturers of battery powered products should take this into account and calculate the size of the battery compartment accordingly. In addition, no sharp edged components should be placed in the immediate vicinity of the battery compartment, as they could potentially damage the battery.

Finally, lithium polymer cells require protective electronics for safe operation. This “Protection Circuit Module” (PCM) interrupts the circuit in critical operating conditions such as overcharging, short circuit or deep discharge.

As you can see: lithium polymer batteries are as powerful as they are demanding. For this reason, Jauch supports its customers throughout the entire project phase: from planning to developing the right battery pack and programming the right protective electronics. An overview of the entire Jauch portfolio of lithium polymer batteries can be found here.

If you would like to learn more about the production, chemical functionality and safe operation of lithium polymer batteries, you are welcome to download our whitepaper.

Deutsch

Deutsch