What you always wanted to know about quartz crystals, but didn’t dare ask until now … – Why does a quartz crystal have to be hermetically sealed?

At the end of the complex production of a quartz, or rather the small quartz disc, the quartz blank, it has to be mounted in a housing that is then hermetically sealed. But why does this seal have to be absolutely airtight?

“The hermetic sealing of the housing has less to do with the quartz blank itself. Rather, it concerns the sensitive silver electrodes that were vapour-deposited onto the quartz blank in a high vacuum during the manufacturing process,” says Mathias Laskus, technical support engineer for frequency control products at Jauch.

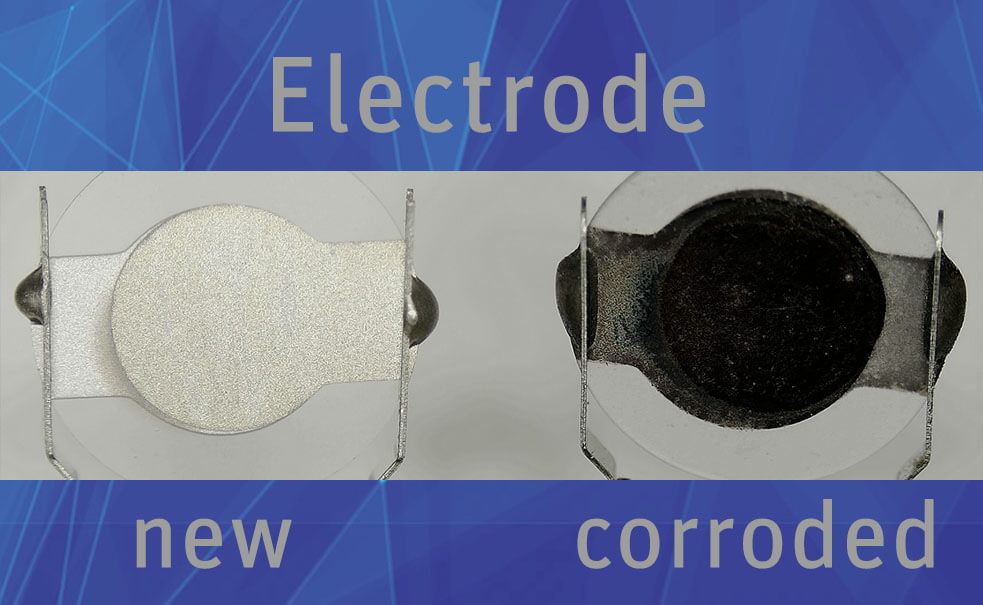

The electrical oscillation is transferred to the quartz blank via the electrodes on both sides. For this purpose, the ideal surface chosen during development should have optimal contact and the highest possible conductivity. Oxidation must therefore be avoided at all costs and would at least negatively influence the electrical parameters and, in extreme cases, lead to failure.

“For this reason, the welding of the housing, i.e. the lid with the ceramic base, takes place under a dry nitrogen atmosphere” explains Mathias Laskus.

In this way, both during resistance welding of the metal lid (seam seal method) with the ceramic base and during remelting of the glass frit between the ceramic lid and the ceramic base (glass seal method), the electrode is protected from corrosion at all times by the protective gas. With good sealing under the best protective atmosphere, there is in principle nothing to prevent the component from having an almost unlimited life expectancy.

Deutsch

Deutsch